touch-proof and robust

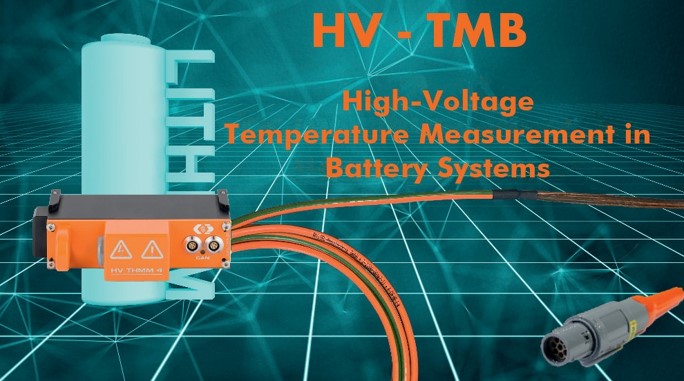

Best results for High Voltage Temperature Measurement in Battery Systems with HV-TMB from Rössel

The specially developed HV cables are scoop-proof and robust. The orange-coloured outer sheath made of PUR material characterises the cables as a product for use for the high-voltage range in vehicle electrical systems. They are particularly suitable for space-saving applications with their small diameter..

As cables are frequently exposed to chafe marks on body parts, the HV cables have a blue intermediate sheath. If the blue intermediate sheath becomes visible, this indicates that the cables are no longer operationally reliable.

The special, coded and fully-insulated connection plug offers additional contact protection even if the cables are not connected to measurement modules.

High demands

High-performance batteries in the e-mobility sec- tor have to meet stringent requirements. Short charging times with high currents, as well as ma- ximum capacities for large ranges when operating the vehicles are required. The provision of further components in the e-mobility sector also stretches the battery systems and other components to their limits.

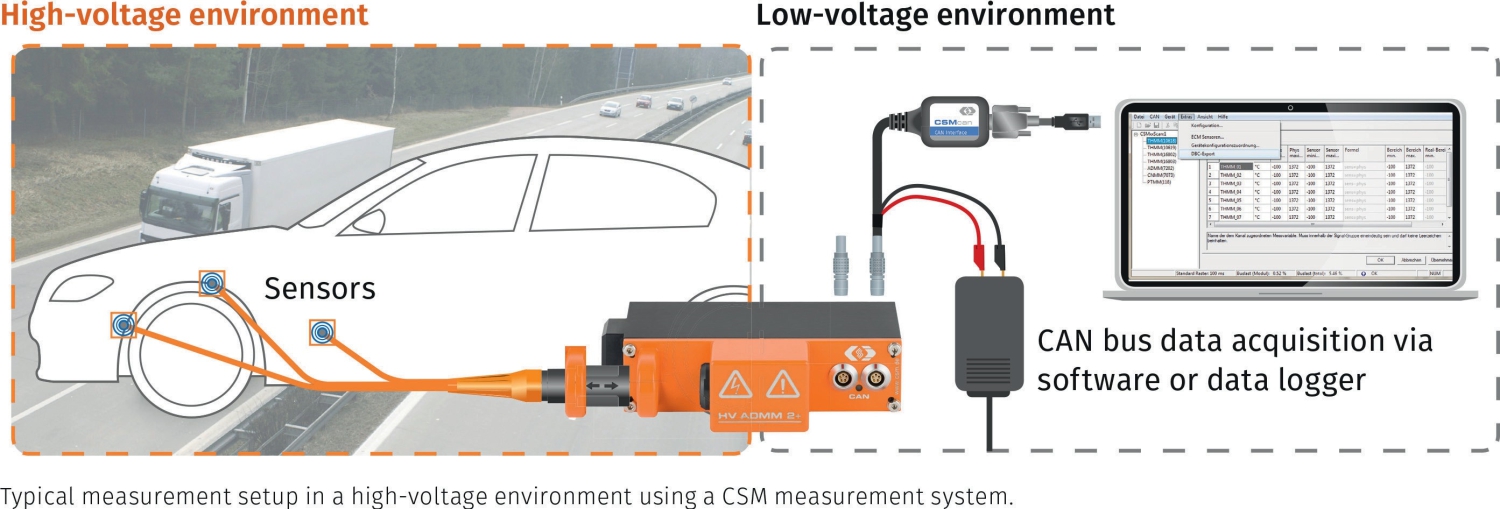

Special measuring systems

A not insignificant part of the energy provision is converted to heat, which has to be detected, moni- tored and regulated. Special measurement systems, which have to meet the specific safety requirements, are used in the region of development and applica- tion of modern battery systems and the associated high operating voltages.

TÜV-tested

Rössel-Messtechnik offers sensor cables which are ready for connection for measuring the tem- perature on high-voltage components from the e-mobility sector. Our high-voltage cables, which have been verified by the certification company, TÜV-Süd, can be directly connected to high-volta- ge temperature measurement modules and thus provide easy-to-use sensor technology for measu- rements within and outside battery components.

Each sensor cable is tested with AC and DC voltages in a high-voltage test bath by means of an established testing method. The result is recorded and documented.

Each sensor cable is given a unique serial number so it can be traced back to the production process. Delivery is made in individually packaged and sealed PVC bags with safety instructions.

| Operating temperature: | -40 to 150 °C |

| Dielectric strength: | 3.7 kV AC and 6 kV DC |

| Outer sheath: | PUR |

| Recorded HV test | |

| Routine test |

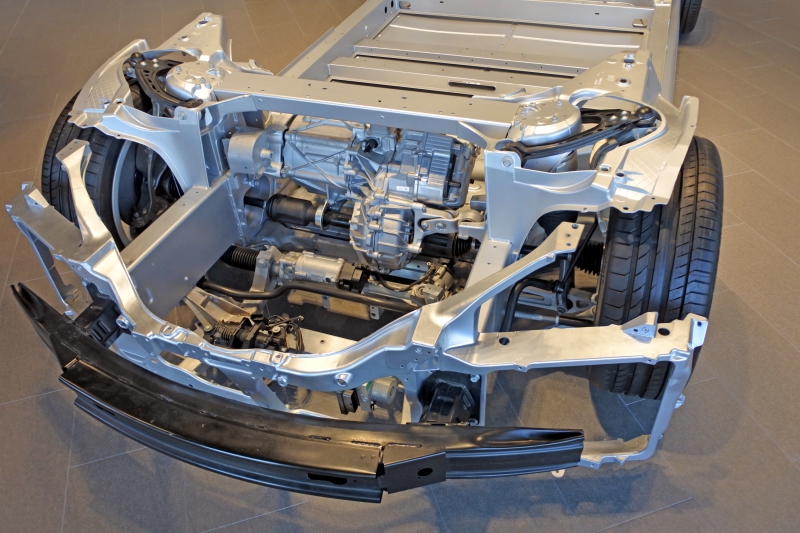

E-technology is the key to maintaining our mobility.

The drive train of e-vehicles is designed comple- tely differently compared to vehicles with internal combustion engines. Battery systems and electric motors are main components here, but com- ponents such as power electronics, alternator, cooler and possibly transmission also play a decisive role.

Only lithium ion batteries are currently installed in e-vehicles. They are impressive on account of their long life cycle and a large energy density. Thousands of lithium ion cells are concentrated in a battery block.

The electric motor as drive element plays a cen- tral role, although the term ‘electric motor’ is not quite correct, as the drive element can also be used as a generator and is also used accordingly in the recuperation.

The power electronics control the change in voltage in driving mode and charging mode. In this case, the electronics convert the electrical energy into the voltage level and waveform necessary for each consumer. A key feature is the high-voltage vehicle electrical system via which all components are connected to one another.