Hochvolt-News

Thermal Runaway

Thermal runaway and thermal propagation are important parts of the safety considerations in the development of battery systems for electric and hybrid vehicles.

Thermal runaway, the thermal runaway of a cell, and thermal propagation, the propagation of a thermal event from cell to cell in a battery, are among the greatest safety challenges in the operation of lithium-ion batteries, as they are now increasingly used in the growing segment of electromobility.

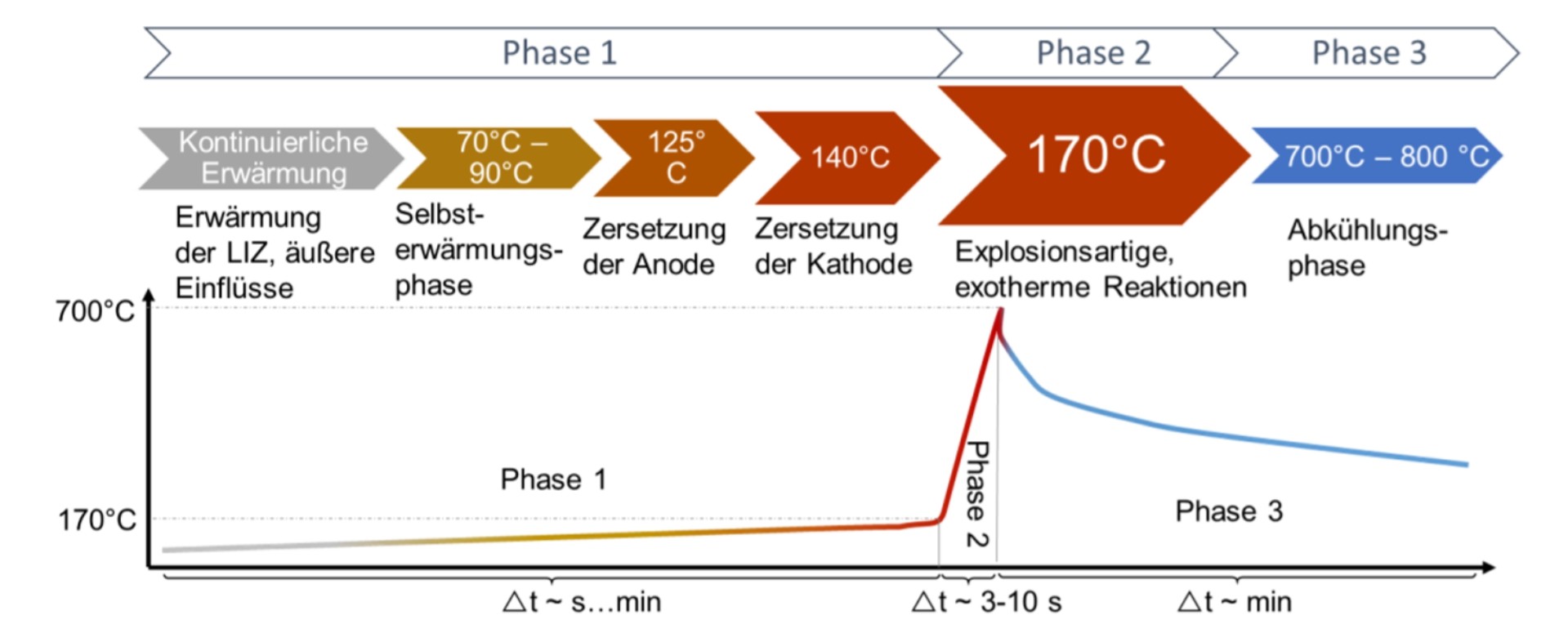

If charging and discharging currents, cell voltage and temperature are exceeded, the service life of the batteries can be significantly shortened and a thermal runaway (thermal runaway) can even occur. With thermal runaway, the battery becomes very warm very quickly when a temperature limit is exceeded. The heat triggers further reactions (thermal propagation), so that within a short period of time

several hundred degrees are reached within milliseconds - the battery ignites (exothermia) or explodes. The temperature at which a thermal runaway occurs depends on the battery cell and the factors that caused the temperature rise. It can already become critical at 60°C. Possible causes are an internal or external short circuit and excessive currents during charging or discharging.

The mechanical properties of the battery cell also play a role. This is because a short circuit can occur when material penetrates a battery cell (traffic accident / collisions) or it is deformed. When designing battery modules and packs, attention must be paid to mechanical stability. It may be advisable that they do not exceed a certain size or number of cells.

The decisive factor in thermal runaway is temperature.

Precise monitoring and effective thermal management are therefore essential. The challenge is that the temperature can usually only be measured on the surface of the battery cell, not inside. However, only a thermal model of the battery cell can be used to deduce the internal temperature from the external temperature.

Accordingly, in the development of battery modules, special attention should be paid to the temperature inside the battery modules and the maximum temperatures should be measured up to thermal runaway and also beyond up to thermal propagation.

The performance of the thermal management under the aspect of vehicle safety can thus be sufficiently tested.

In addition, the further behaviour of the cells, the battery module and the housing materials up to self-ignition is also a safety aspect.

Information about the resulting temperatures up to the melting of materials is an important parameter for checking events up to exothermia.

Standard temperature sensors, or semiconductor sensors, cannot withstand these rising temperatures, which can even reach over 700 degrees Celsius. Semiconductor sensors can only measure temperatures up to a maximum of 125 degrees Celsius and thermocouples or resistance thermometers up to a maximum of 300 degrees Celsius due to the insulation materials used.

However, Rössel-Messtechnik offers a transition HV thermocouple with which the temperature can even be measured up to 1000 degrees Celsius and beyond.

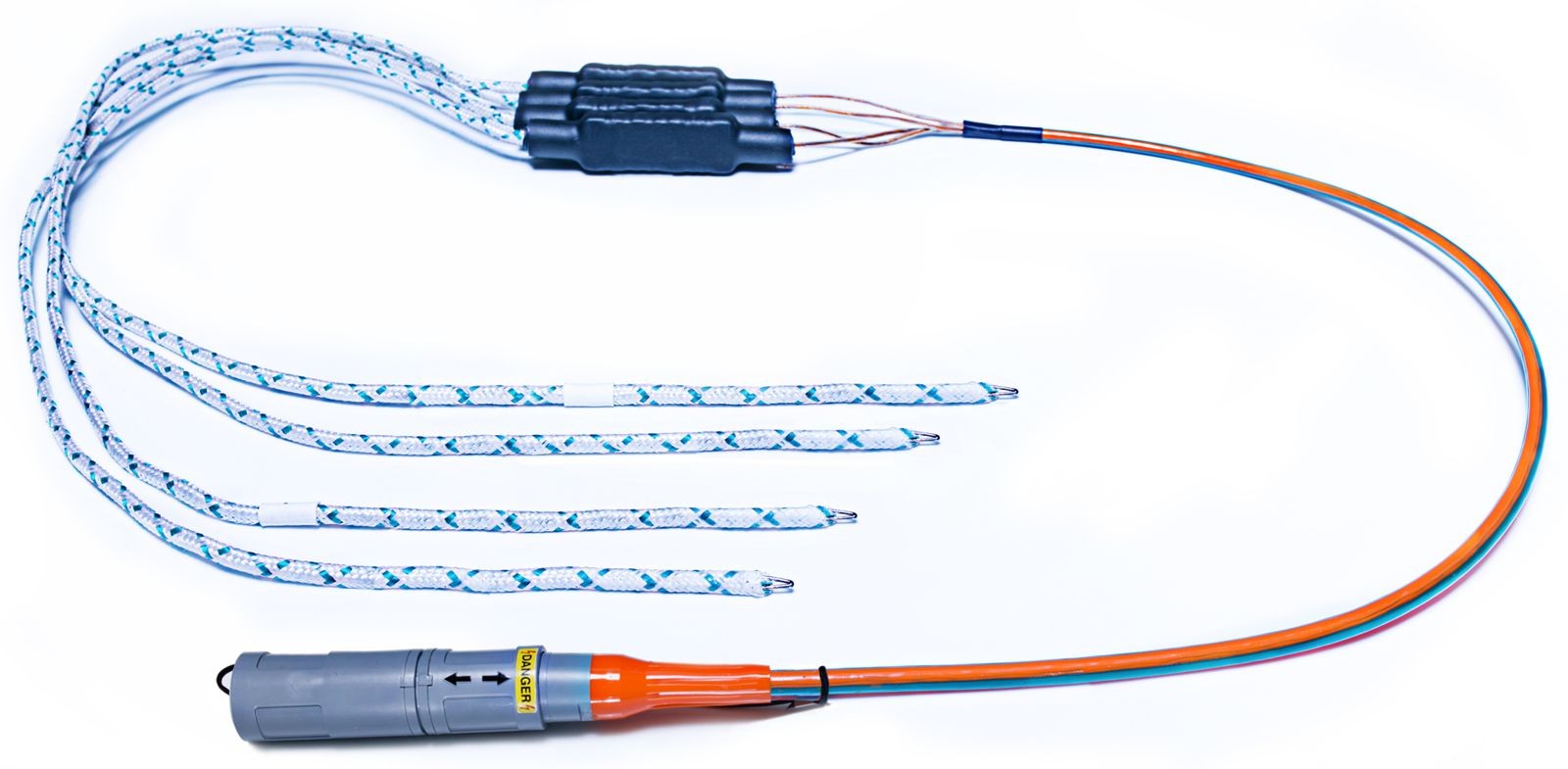

Our transition HV thermocouple, called TR-HV-TE for short, consists of a ceramic high-temperature cable which is connected directly to our HV-safe temperature sensor.

This allows all common HV measuring modules to be connected in order to record and evaluate the temperature curve from thermal runaway, through thermal propagation to exotherm without interruption.

4-channel transition high-voltage sensor

4-CH-TR-HV-KN-K

High temperature resistant cable

| Material | Ceramic fibre |

| Temperature-resistant | up to 1200 °C |

High voltage safe line

| Material | PUR-FEP-Kapton |

| High-voltage resistant | up to 6000 V DC |

For more information about our TR-HV-TE, please contact us.